OUR APPROACH

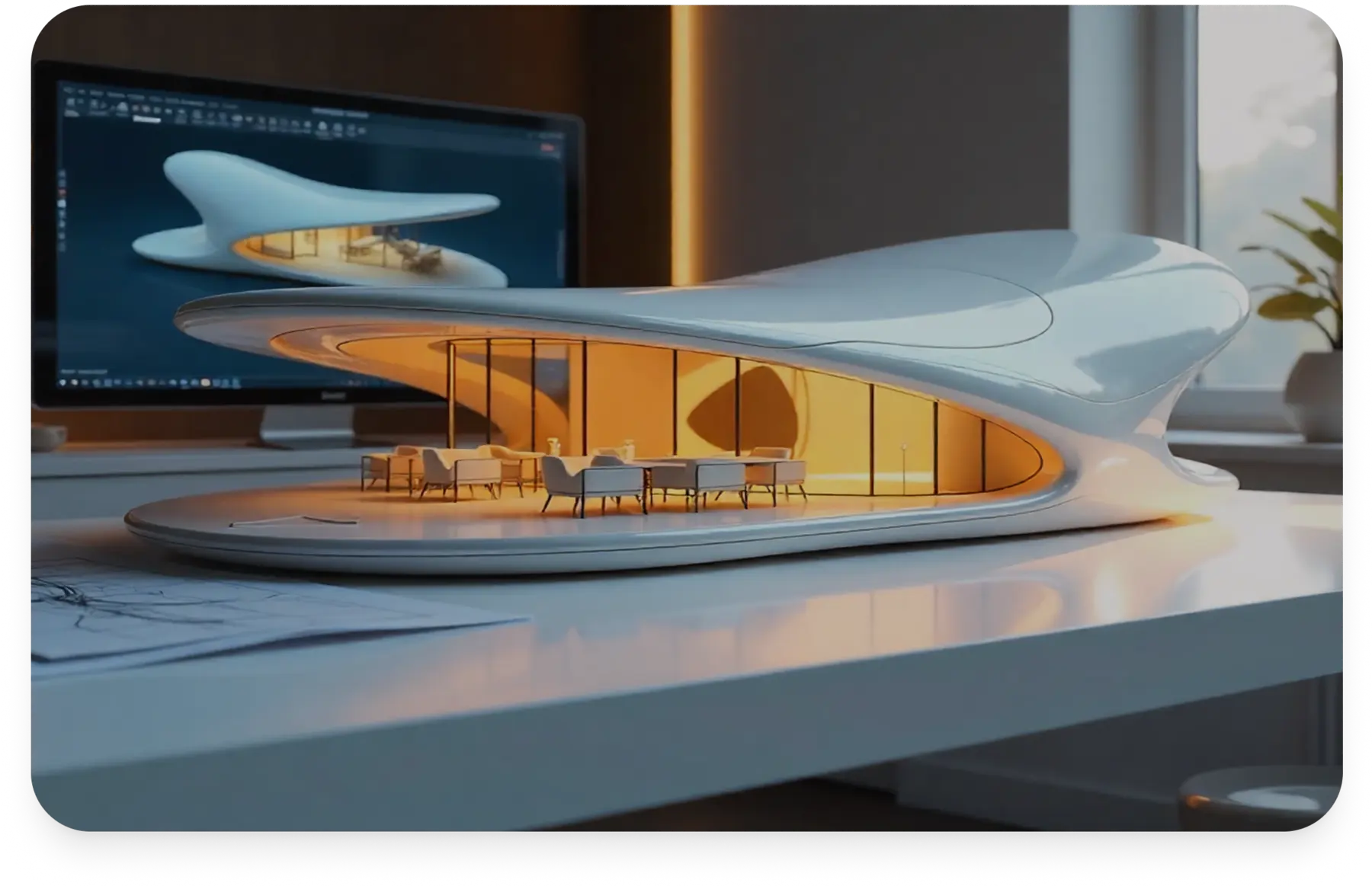

We create custom, hand-built models in-house, tailored to the specific needs of each project. Our approach combines traditional craftsmanship with advanced fabrication methods to ensure accuracy and quality. 3D printing is also offered as a standalone service, using a range of materials and technologies suited to diverse forms and applications.

get in touchwhat we do

MODELING & 3D PRINTING services

Models

We create exquisitely detailed physical models across all scales and industries, including architectural, commercial, industrial, and entertainment sectors. Our expert craftsmanship features integrated lighting, realistic landscaping, removable components, and high-quality finishes, delivering precise and visually compelling scale models tailored to your project’s unique specifications and requirements.

3D Printing & Scanning

We provide a comprehensive range of 3D printing services, from high-accuracy 3D scanning to fully finished, production ready parts. Our expertise includes advanced resin 3D printing for superior surface detail, multiple metal 3D printing technologies for durable and functional components, and a wide selection of composite 3D printing options for lightweight, high-performance applications.

Built for Bold Ideas

We take a collaborative, open approach and work with a diverse range of clients - individuals, businesses, artists, and designers alike.

Architects & Developers

Marketing & Advertising

Film, TV & Entertainment

Exhibitions & Events

Retail & Commercial

Aerospace & Transportation

what we do

Models we create

ARCHITECTURAL & INTERIOR MODELS

We craft detailed architectural models that include building exteriors, interior layouts, and full site planning. These may range from individual structures with landscape features, to larger developments with multiple buildings and shared outdoor areas. Models can incorporate sectional cuts or removable roofs to reveal interior spaces with clarity and precision.

Commercial & Promotional MODELS

Our commercial models include miniature branded environments such as storefronts, restaurants, and kiosks. These are often used in marketing campaigns, presentations, and exhibitions. We also produce sculptural and interactive models for trade shows, pop-up installations, and brand activations.

Industrial & Transportation MODELS

We produce high precision scaled models of vehicles, ships, aircraft, and industrial machinery. These models are built to accurately represent form, structure, and function, making them ideal for presentations, exhibitions, and technical reference.

Entertainment & Set Design Models

We create detailed miniatures, scenic elements, and set design models for film, television, and live performance. These models support the planning of spatial layouts, lighting, and camera movement. We also create concept models for theme parks and immersive environments, used in early design and development stages.

OUR PROCESS

HOW IT WORKS

We use eco-friendly materials and methods to minimize waste, creating art that inspires while respecting the environment.

PERSONALIZED CONSULTATION

We begin by deeply understanding your vision, style, and the unique story behind your custom artwork.

DESIGN & PRODUCTION PLANNING

A tailored production plan is created to fit your needs and budget, with custom design included if required.

CRAFTSMANSHIP & DELIVERY

We handcraft your piece - bringing your vision to life with exceptional attention to detail and high-quality craftsmanship.

PERSONALIZED CONSULTATION

We begin by deeply understanding your vision, style, and the unique story behind your custom artwork.

DESIGN & PRODUCTION PLANNING

A tailored production plan is created to fit your needs and budget, with custom design included if required.

CRAFTSMANSHIP & DELIVERY

We handcraft your piece - bringing your vision to life with exceptional attention to detail and high-quality craftsmanship.

Our tools & materials

Materials We Work With

We work with a range of materials using a mixed-model approach tailored to each piece and our clients' unique requirements.

OUR METHODS

Cutting-Edge 3D Printing Technologies We Use

To deliver exceptional quality and precision, we leverage a variety of state-of-the-art additive manufacturing technologies

FDM Printing

SLA Printing

SLS Printing

Color Jet Printing

MJF Printing

FDM Printing

SLA Printing

SLS Printing

Color Jet Printing

MJF Printing

OUR PROJECTS

Each piece is brought to life through a carefully tailored process - blending advanced technology with artistic technique.

Balance of Power

Playful Reflection

Cheval Vuitton

Soft Geometry

Essence Azul

Buffer

Symphony in Motion

Balance of Power

Playful Reflection

Cheval Vuitton

Soft Geometry

Essence Azul

Buffer

Symphony in Motion

FAQs

Everything You Need to Know

From production methods to timelines, find quick answers to common questions about our services.

What are the differences between SLA, SLS, and FDM 3D printing?

Each technology serves a different purpose based on detail, strength, and size: SLA (Stereolithography): Produces smooth, highly detailed models using UV-cured resin - ideal for intricate designs and presentation models. SLS (Selective Laser Sintering): Fuses powdered materials with a laser to create strong, functional parts - perfect for industrial use and prototypes. FDM (Fused Deposition Modeling): Uses thermoplastic filament to build durable, cost-effective parts - ideal for concept models and larger components.Are you able to 3D print transparent or translucent models or items?

Yes, we can print using transparent or semi-transparent materials. These are commonly used for medical models, lighting prototypes, and aesthetic product designs that require visual depth or internal visibility.Do I need to provide a 3D file for your 3D printing & model making services?

Yes, a digital 3D file is required for all 3D printing and model-making projects. We accept standard file formats such as STL, OBJ, STEP, STP, and DWG. If your file is in a different format, please contact us to discuss compatibility and possible solutions.How long does it take to complete a model or 3D printed part?

Production time depends on the part, model’s size, complexity, and material. Simple parts may take 1 to 3 days, while large or detailed models and prints can take up to several weeks. We’ll provide a clear timeline after your initial consultation.What level of detail can I expect in your model making work?

Our models are built to the highest standard, with precise textures, clean edges, and accurate representations of your designs. We also offer advanced features such as LED lighting, motorized parts, and interactive elements upon request.Do you offer finishing and post-processing services?

Yes. Post-processing is available as an optional add-on to our 3D printing services. This includes expert sanding, painting, powder coating, and full assembly. All models we craft are fully painted and finished, requiring no additional work before presentation or use.Is 3D printing an environmentally sustainable option?

Yes. Compared to traditional manufacturing, 3D printing generates significantly less waste, as it only uses the material required for each part. We also offer eco-friendly materials for clients seeking sustainable solutions.